Nankai Gallery

Nankai Chemical in our daily life

The colorful designs at that time and the catchphrases symbolizing the times are freshly impressive even today.

HISTORY 100-year history of Nankai Chemical

| Story of founding | Trajectory of originality | ||||||

|---|---|---|---|---|---|---|---|

| Chapter 1. Start-up |

Chapter 2. Takeoff |

Chapter 3. Trying times |

Chapter 4. Sound business |

Chapter 5. Overcome |

Chapter 6. Reformation |

Chapter 7. Challenge |

|

Story of founding

Yonezo Koizumi, one of the founders of Nankai Chemical Co., Ltd., was born in Arida City, Wakayama Prefecture, as the second son of Zenzaemon Tanaka.

The Tanaka family is well-known for their contribution to the encouragement of local new industries in the Edo era.

Yonezo was adopted by the Koizumi family and entered Wakayama Junior High School.

Sulfuric Acid Bleaching Powder Co., Ltd. was established in Sakai City, Osaka Prefecture in 1896. Since his brother, Zenkichi Tanaka, was the manager of the company, he worked under his brother to learn the manufacturing methods of bleaching powder and sulfuric acid and expand his network in Wakayama and Sakai.

Sulfuric Acid Bleaching Powder Co., Ltd. in 1900

The Russo-Japanese War broke out in 1904. The government encouraged new industries and strengthened the military administration, resulting in special demands and an entrepreneurial boom in the industry.

At that time, the production of Kishu flannel was blooming for the increased demand of military uniforms in Wakayama. The processing technology of cotton flannel has shifted from hand weaving to power loom. Particularly, printing technology greatly advanced.

The demand of bleaching powder was markedly increased because it was indispensable to the pre-printing process.

Vancouver in 1902

Yonezo, who had traveled to the United States and therefore was familiar with domestic and overseas circumstances, sensed an opportunity to establish a chemical company. Particularly, he thought that the businesses of bleaching powder, sulfuric acid, and superphosphate, which he had experienced at Sulfuric Acid Bleaching Powder Co., Ltd. in Sakai, were promising.

At that time, hydroelectric power generation was also developing by abundant water. Since abundant high-quality sulfide ore was produced from the Iimori mine in Wakayama prefecture, the raw material for sulfuric acid could be obtained at a low cost. These factors paved the way for starting a new business.

Yonezo immediately contacted entrepreneurs related to Kishu funnel and local wealthy people.

As a result, those interested, such as Shichibei Kitajima, a big business person in the local cotton fabric industry, decided to invest.

Bleached cotton cloth of Kinokawa

The main logistics at that time was shipping. In the Kinokawa River, ships were routinely used for transportation.

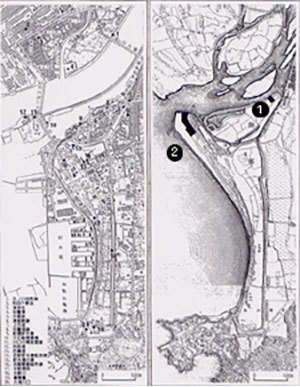

Aogishi, relatively close to Nezumijima, was selected for the plant, because it was the largest port in Wakayama, with regular flights between Wakayama and Osaka.

On October 26, 1906, Nankai Sulfur Fertilizer Co., Ltd., the predecessor company of Nankai Chemical Co., Ltd., was established.

Yonezo became the manager because he was familiar with bleaching powder and sulfuric acid production technology. Yonezo Koizumi was 34 years old in that autumn.

1. Nezumijima and 2. Location of the Aogishi Plant Past and present

Chapter 1. Start-up

1906-1924

Nankai Sulfur Fertilizer Co., Ltd. was established under the leadership of Yonezo Koizumi who had experienced the businesses of bleaching powder, sulfuric acid, and fertilizer, with financial support from businesspersons in the cotton flannel industry and wealthy asset owners willing to invest in the company in Wakayama.

Kii Mainichi Shimbun (November 9, 1906)

The headquarters were located at 1570 Oaza Minato, Minato-mura, Kaiso-gun, Wakayama Prefecture (commonly known as Nezumijima), where the first step was marked for the foundation of Nankai Chemical.

At that time, i.e., immediately after the end of the Russo-Japanese War, the special demand and entrepreneurial boom, boosted by the war-time special demand, were coming to an end.

However, at the same time as the foundation, the markets of sulfuric acid and fertilizer rapidly deteriorated because of excessive supplies. So, some sponsors were worried about the future, leading to the delayed payment of shares.

Therefore, Yonezo Koizumi decided on capital reduction and produced and distributed only bleaching powder with a high demand in the local area. Also, the company name was changed to “Nankai Bleaching Powder Co., Ltd.”

Announcement of capital reduction/company name change

(February 3, 1907, Kii Mainichi Shimbun)

At the peak of cotton flannel, so-called Kishu flannel, Wakayama Prefecture had an about 60% share of the national market. Since a large amount of bleaching powder is used for bleaching, Nankai Bleaching Powder launched its business satisfactorily by taking full advantage of production in areas with high demands.

The management team planned to increase the production of bleaching powder, while paying attention to the possible in-house production of sulfuric acid as a raw material and distribution of sulfuric acid as products. By taking advantage of the procurement of iron sulfide ore, a raw material for sulfuric acid production, from the local Iimori mine, the company decided to start sulfuric acid production.

In 1910, the company purchased a piece of land in Aogishi, closer than the Nezumijima Plant, which had become too small, and started construction of a plant for sulfuric acid production. The construction was completed in 1911, starting production. Subsequently, a second plant for sulfuric acid production was built in 1913, with a monthly production of 1,000 tons.

Commemorated the completion of Aogishi Sulfuric Acid Plant (February 1911)

Under such circumstances, caustic soda, whose demand had increased as a raw material for various industrial uses, was mostly imported from Europe and the United States, and so was high-quality caustic soda produced by electrolysis. If electrolytic soda was fully produced in Japan, a large amount of bleaching powder would be produced as a by-product, posing a critical issue for Nankai Bleaching Powder.

Thus, Yonezo Koizumi decided to take the initiative in entering the soda business and acquired the patent of Nelson-type electrolysis from Warner Chemical Co., Ltd. in the United States. In 1916, Nankai Soda Co., Ltd. was established as a Nelson-type electrolytic soda company. Ren Shoda was dispatched to the United States to learn the technology. In 1918, a new plant, built in Kozaika, Miyamae-mura, launched its operation. Its annual production was 720 tons of caustic soda and 840 tons of bleaching powder.

Warner Chemical Company

Mr. and Mrs. Warner (March 1916) at Wakayama Castle in Wakayama Prefecture

Nelson electrolysis equipment introduced in Nankai Bleaching Powder

In 1916, Dainihon Jochugiku Co., Ltd. was established in Nezumijima. In 1918, Hokkai Soda Co., Ltd. was established in Fushiki, Toyama Prefecture. In 1917, our company participated in the establishment of Yura Dye Co., Ltd., the first manufacturer of medical phenolic acid and various dyes in Japan.

In 1919, a Valentina-type nitric acid plant was newly established in Aogishi. Thus, the company made a leap while accurately reading the changes of the times.

Nankai Bleaching Powder Building in the era of Taisho

At that time, 27 companies, including Nankai Bleaching Powder, were listed on the Wakayama Stock Market.

Opened Wakayama Suginobaba Sales Office (1923)

(photographed in 1929)

Chapter 2. Takeoff

1925-1937

The material for dissolving raw materials, such as paper bush, was switched from wood ash to caustic soda. Thus, the demands for soda and bleaching powder, including consumption of bleaching powder for bleaching, rapidly increased.

Under these circumstances, Tosa Sulfur Co., Ltd. was established in 1925 at the former site of Tosa Soda Co., Ltd., which had been dissolved in 1923 because of the Great Kanto Earthquake, and a Nelson-type electrolysis facility was constructed. Yonezo Koizumi was appointed as the president. Ren Shoda took lead in the construction of the caustic soda and bleaching powder manufacturing facilities.

Shoda (plant manager) and Koizumi (president)

In 1931, the Manchurian Incident broke out. The imports of foreign goods were blocked and exports increased, promoting domestic industries. During this period, our company also focused on research and development and developed various products, and thus actively expanded the business.

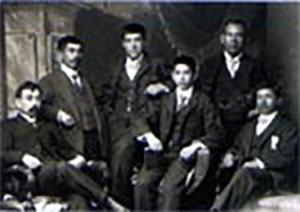

The Kozaika Plant aimed to build additional plants for new products, “chloropicrin” and “carbon tetrachloride,” and establish R & D and distribution systems for subsequent new products. Young engineers, including Sadao Murai, who joined our company in 1927, played a central role. Murai became the manager of the Kozaika Plant only eight years after joining the company, contributing to the development of most products during this period.

Young engineers

Established Nankai Oil (currently Kuroe District, Nankai City)

Registered trademark of Nankai Chemical Co., Ltd. at that time

Chapter 3. Trying times

1938-1953

The president was Etsuji Nakayama, the founder of Nakayama Steel Works. Yonezo Koizumi was appointed as the managing director. Thus, Nankai Chemical became the Chemistry Department of Nakayama Steel Works.

Yonezo Koizumi at the merger

During the air raid on Kochi City in July 1945, the Tosa Chemical Plant, the main plant for military goods, was destroyed by incendiaries and bombs. Although the two plants in Wakayama were not directly damaged, production stopped because the electric power required for production could not be transmitted.

In August, the war finally ended. All the plants of Nakayama Steel Works were suspended.

Tosa Plant immediately after the war (1945)

The employees who had protected the home front, those who had been demobilized from battlefields, and the employees and workers who had returned from outside gradually but strongly resumed production.

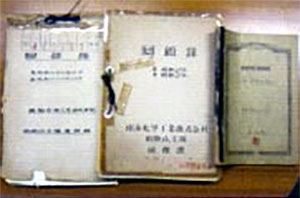

3 Memoirs and important diaries of plants

Second production plan of the company

In 1953, the unions of Wakayama and Tosa joined the Labor Union, establishing a joint federation of both unions.

Eiji Shioji was the executive chairperson.

Chapter 4. Sound business

1954-1972

As the presence in the international community had grown for the Tokyo Olympics and the Japan World Exposition, Japan had grown to compete for the first and second places in the world in various industries, such as shipbuilding, steel, automobiles, home electrical appliances, synthetic fibers, and chemical fertilizers.

However, environmental pollution occurred as a side effect of high economic growth. Companies pursuing economic expansion and growth reflected on their past conducts with an increasing interest in environmental issues.

At that time, Nankai Chemical actively worked to improve productivity and reduce costs.

Two methods, i.e., the diaphragm and mercury methods, had been employed for soda production. However, caustic soda produced by the diaphragm method is unsuitable for inferior quality for chemical fibers whose demand had been increasing. Thus, in 1962, the Kozaika Plant invented its own method, i.e., the mercury method.

Completion of a mercury electrolysis facility (Kozaika Plant) (1962)

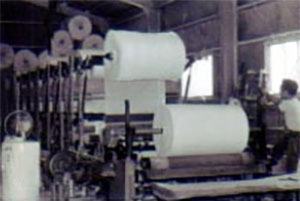

In 1956, Nankai Paper Co., Ltd. was established. The headquarters were located at the Asahi Plant in Kochi City to carry out production and distribution using a three-plant system with the Takaoka Plant in Tosa City and the Ueno Plant in Ueno City, Mie Prefecture. As originally intended, this greatly contributed to the distribution of caustic soda, bleaching powder, and bleaching liquid at the Tosa and Kozaika Plants.

Scene of the Nankai Paper Plant

Chapter 5. Overcome

1973-1982

Under such circumstances, in 1974, President Yasuyuki Nakayama retired and Takashi Ban became the new president. In such a difficult business environment, the new management team, led by the president, actively tackled various issues.

To address environmental issues, the Kozaika Plant established a closed system for mercury electrolysis to prevent mercury discharge from the plant. Aogishi and Tosa Plants strengthened environmental measures, such as the installation of wastewater treatment equipment and prevention of air pollution.

Ceremony of the completion of a new hydrogen-mixed combustion boiler (Tosa Plant)

(October 1980)

Furthermore, the company increased the capital and sold underutilized real estate, and decided to withdraw from dead-end businesses.

Shield of the Agency for Natural Resources and Energy Commissioner's Award

Chapter 6. Reformation

1983-1990

Also, the manufacturing monitoring was rationalized, leading to a significant reduction in labor costs.

Converted to the IM method in the Kozaika Plant (May 1986)

Yasuo Shimada, who was seconded from Nakayama Steel Works to be appointed as the director of the Production Department, played a central role. Employees actively worked on the plans as announced one after another. Under the slogan “Lively New Nankai,” the company was drastically reformed in a short period of time.

In 1986, the organization was drastically reformed. This aimed to establish a management base to address changes in the environment and industrial structure, as well as to renew technologies and fields, rationalize personnel, reduce costs, and strengthen sales capabilities.

Also, the company strengthened the R & D Department for Nankai Chemical to develop as a unique chemical manufacturer. An R & D office was placed in the Kozaika Plant, and the R & D Tosa Branch Office in the Tosa Plant. Furthermore, besides the 1st and 2nd R & D Offices, the Development Project Office was established in the R & D Department to reinforce the R & D capabilities.

For example, a research center with state-of-the-art analytical equipment was established in the Kozaika Plant, thus completing the research and development system.

General Research Center

Chapter 7. Challenge

1991-

Then, Japan entered a deflationary era. Nankai Chemical had difficulty with maintaining the conventional management.

Under these circumstances, Yasuo Shimada, appointed as the president, tried to transform the company for survival in the 21st century by changing everything, based on new ideas, from the manufacturing method in the plants to the sales methods.

As described in the plan, “To transform the company for survival in the 21st century, we will place the highest priority on the profitability of all products and thoroughly focus on the basics of production to provide high-quality products from customers’ viewpoints, with all business establishments pursuing profitability.”

Poster of the Rainbow Bridge Plan

We are also promoting strategic “expansion of sales bases,” “spin-off,” and “M & A” for the future.

Poster of Sunrise Plan